China Standard Totally Oil-Free Nitrogen N2 Gas Compressor with UL Certificate with High Quality

Product Description

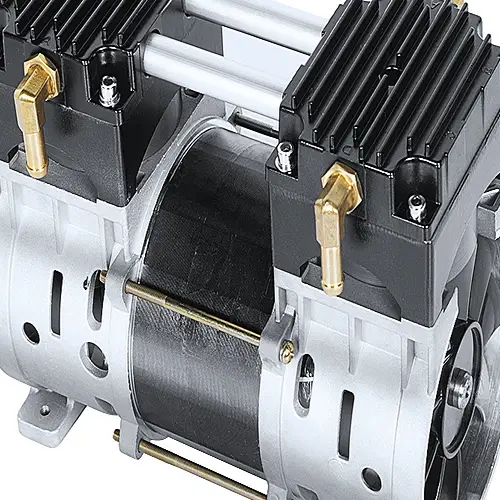

The China Standard Totally Oil-Free Nitrogen N2 Gas Compressor with UL Certificate is a high-quality oil-free booster compressor designed for various industrial applications. It ensures the delivery of clean and pure nitrogen gas without any oil contamination.

Product Specifications

| Product Name | Oil-Free Booster Compressor |

| Model No | BW-3/5/10/15/20/30… |

| Inlet Pressure | 0.4Mpa(G) |

| Exhaust Pressure | 150/200Mpa(G) |

| Type | High Pressure Oil Free |

| Accessories | Filling Manifold, Piston ring, etc. |

Oilless High Pressure O2 Compressor Specification

| Oilless High Pressure O2 Compressor Specification | |||||

| NO | Volume | Inlet Pressure | Outlet Pressure | Type | Cooling type |

| 1 | 1-3m³ | 0.3-0.4MPa | 15MPa | 2 lines 4 stages vertical type | Wind |

| 2 | 4-12m³ | 0.3-0.4MPa | 15MPa | 2 lines 4 stages vertical type | Wind |

| 3 | 13-40m³ | 0.3-0.4MPa | 15MPa | 3 lines 3 stages W type | Water |

| 4 | 13-60m³ | 0.2-0.4MPa | 15MPa | 2 lines 4 stages vertical type | Water |

| 5 | 40-80m³ | 0.2-0.4MPa | 15MPa | 4 lines 4 stages S type | Water |

| 6 | 80-120m³ | 0.2-0.4MPa | 15MPa | 4 lines 4 stages S type | Water |

Inquiry Information

If you have an inquiry for our compressors, please provide the following information:

- Compressor working medium: If single gas, what is the purity? If mixed gas, what is the gas content in liters?

- Suction pressure (gauge pressure): _____bar

- Exhaust pressure (gauge pressure): _____bar

- Flow rate per hour for compressor: _____Nm³/h

- Compressor gas suction temperature: _____ºC

- Compressor working hours per day: _____hours

- Compressor working site altitude: _____m

- Environment temperature: _____ºC

- Is there cooling water available on the site? ______

- Voltage and frequency for 3 phase: ________________

- Is there water vapor or H2S in the gas? ______

- Application for compressor? __________

Ever-Power Group, a leading supplier of industrial products, offers a wide range of products including agricultural gearboxes, power output shafts, sprockets, fluid couplings, worm gear reducers, gears and racks, roller chains, pulleys and pulleys, planetary gearboxes, timing pulleys, bushings, and more. We pride ourselves on providing high-quality products, competitive prices, and excellent customer service. We also welcome custom drawings and samples. Choose Ever-Power Group for all your industrial product needs.

Frequently Asked Questions (FAQs)

1. What is the working medium for the oil-free booster compressor?

The working medium is nitrogen gas, ensuring a clean and oil-free operation.

2. What are the inlet and exhaust pressures of the compressor?

The inlet pressure is 0.4Mpa(G), and the exhaust pressure is 150/200Mpa(G).

3. What cooling types are available for the oilless high-pressure O2 compressor?

The cooling types include wind cooling for smaller volumes and water cooling for larger volumes.

4. Can the compressor handle mixed gases?

Yes, the compressor can handle mixed gases. Please provide the gas content in liters for accurate operation.

5. Are customization options available for the compressors?

Yes, we offer customization options for our compressors. Customers can provide drawings and samples for personalized solutions.

All the content of this page is from the Internet, the content is only as a reference for product selection. Our products are replacement parts and not original spare parts. We are not the holder of the original trademarks of the content. Our products are only suitable for after-sales replacement parts and not original spare parts. Our replacement parts can be perfectly adapted to the original spare parts. If you need to buy original spare parts, please contact the original factory to buy. If you want to buy original spare parts, please contact the original supplier for purchase.

Performance Characteristics of Nitrogen Compressor

-

Efficient Operation:

The Nitrogen Compressor is designed to operate efficiently, ensuring maximum productivity and minimal energy consumption. It delivers high performance in generating nitrogen gas.

-

Reliability and Durability:

With robust construction and high-quality components, the Nitrogen Compressor offers reliability and durability, ensuring long service life and minimal downtime.

-

Adjustable Pressure:

The Nitrogen Compressor allows for easy adjustment of pressure, providing flexibility in meeting specific application requirements.

-

Low Maintenance:

Thanks to its well-engineered design, the Nitrogen Compressor requires minimal maintenance, reducing operational costs and downtime.

-

Quiet Operation:

The Nitrogen Compressor is designed to operate quietly, minimizing noise pollution in the working environment.

Types and Characteristics of Nitrogen Compressor

There are various types of Nitrogen Compressors available, each with its own unique characteristics:

-

Reciprocating Nitrogen Compressor:

This type of compressor uses pistons to compress nitrogen gas, offering high efficiency and reliability.

-

Rotary Nitrogen Compressor:

Utilizing rotating mechanisms, this compressor provides continuous and smooth operation, suitable for high-volume nitrogen gas production.

-

Screw Nitrogen Compressor:

With twin screws, this compressor delivers consistent and reliable performance, ensuring efficient nitrogen gas generation.

The choice of Nitrogen Compressor material can significantly impact its performance. Different materials offer various advantages:

-

Stainless Steel Nitrogen Compressor:

Provides excellent resistance to corrosion and high temperatures, making it suitable for demanding industrial applications.

-

Cast Iron Nitrogen Compressor:

Offers durability and strength, making it a cost-effective option for general nitrogen gas generation.

-

Aluminum Nitrogen Compressor:

Lightweight and corrosion-resistant, this material is ideal for portable nitrogen gas generation units.

Application of Nitrogen Compressor

The versatility of Nitrogen Compressor makes it invaluable in various industries:

-

Chemical and Petrochemical Industries:

Nitrogen Compressor is used for blanketing, purging, and pressurizing applications in chemical and petrochemical processes.

-

Food and Beverage Packaging:

Nitrogen Compressor plays a crucial role in maintaining product quality and extending shelf life in the food and beverage packaging industry.

-

Electronics Manufacturing:

Nitrogen Compressor is used for nitrogen reflow soldering, preventing oxidation and ensuring high-quality electronic components.

-

Oil and Gas Processing:

Nitrogen Compressor is essential for natural gas dehydration, pipeline purging, and oil well drilling operations in the oil and gas industry.

-

Laboratories and Research Facilities:

Nitrogen Compressor is used for various applications in laboratories and research facilities, including sample preparation, gas chromatography, and mass spectrometry.

Future Development Trends and Opportunities

The Nitrogen Compressor industry is expected to witness significant growth and development in the coming years. Some potential trends and opportunities include:

-

Advancements in Technology:

With the advancement of technology, Nitrogen Compressor will continue to improve in terms of efficiency, reliability, and ease of operation.

-

Increasing Demand from Emerging Industries:

Emerging industries such as renewable energy and healthcare are expected to drive the demand for Nitrogen Compressor, creating new opportunities for market growth.

-

Focus on Sustainability:

The industry is increasingly focusing on sustainable solutions, leading to the development of energy-efficient and environmentally friendly Nitrogen Compressors.

Choosing a Suitable Nitrogen Compressor

When selecting a Nitrogen Compressor, several aspects should be considered:

-

Clear Requirements:

Clearly define the specific application requirements to ensure the chosen compressor meets the desired performance criteria.

-

Material Selection:

Consider the material of the Nitrogen Compressor based on factors such as corrosion resistance, temperature tolerance, and overall durability.

-

Design Optimization:

Look for compressors with optimized designs that offer maximum efficiency, ease of maintenance, and noise reduction.

-

Suppliers and After-Sales Service:

Choose reputable suppliers that offer reliable products and excellent after-sales service, ensuring long-term support and assistance.

-

Cost-Effectiveness:

Evaluate the overall cost-effectiveness of the Nitrogen Compressor, considering factors such as initial investment, energy consumption, and maintenance requirements.

-

Quality Control:

Ensure the Nitrogen Compressor meets industry standards and certifications, guaranteeing quality and performance.

Author: Dream