“`html

“`html

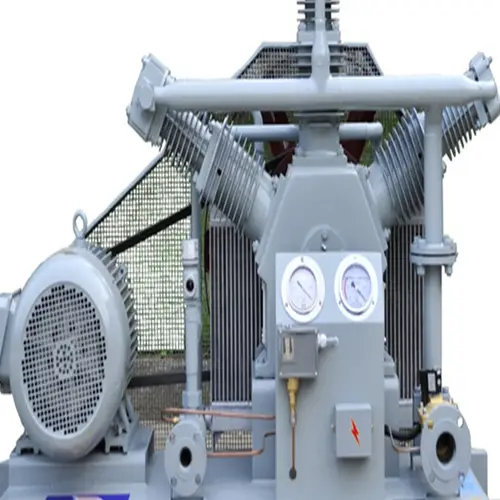

Natural Gas Compressor

The advent of modern industrial processes has necessitated the development of sophisticated gas compression systems. Our Natural Gas Compressor stands as a testament to innovation, expertly designed to accommodate a myriad of gases including natural gas, hydrogen, nitrogen, and ammonia. This versatile vertical screw type, water-cooled equipment is engineered for optimal performance, ensuring maximum efficiency in various industrial applications.

Product Overview

PROCESS GAS CHINAMFG UNIT is a versatile compressor adept at handling diverse gases such as coke oven gas, coal bed gas, water gas, flare gas, and biogas. It plays a pivotal role in gas pressurization across industries like petrochemical, natural gas, coal, and pharmaceuticals.

Unit Features

| 01. High exhaust pressure: Maximum exhaust pressure can reach 5.0 MPa. | 02. Compliance with GB and API standards. |

| 03. Constructed from diverse materials to meet specific gas pressurization requirements. | 04. Pressure vessels and pipelines adhere to GB and ASME standards. |

| 05. Multiple cooling configurations: Water cooling or air cooling options. | 06. Flexible installation: Suitable for indoor machine rooms or outdoor settings. |

Industry Applications

Natural Gas Compressor Unit

This pressurized equipment is utilized in sectors like natural gas, petroleum, petrochemical, and electric power. Its applications range from natural gas pipeline pressurization to BOG gas recovery, ensuring reliable performance across various gas types.

Mixed Refrigerant (MR) Unit

Designed for small-scale natural gas liquefaction, our MR unit excels in helium recovery and is particularly suitable for gases that are prone to leakage. Thanks to its semi-enclosed structure, this unit minimizes construction on-site, enhancing efficiency.

Propane Pre-Cooled Compressor Unit

This unit utilizes propane (R290) to create a refrigeration cycle that efficiently pre-cools natural gas and mixed refrigerants, ensuring superior operational performance.

Non-Energy Type Process Gas Compressor Unit

The CHINAMFG screw compressor is essential for boosting gases like carbon dioxide, ammonia, and hydrogen sulfide. It finds extensive use in industries ranging from petroleum to chemical processing, playing a critical role in gas recovery and pressurization.

Specialized Units

| B1. Screw Carbon Dioxide Compressor Unit: Ideal for CO2 recovery in various industries, ensuring high-quality output for food-grade requirements. |

| B2. Screw Ammonia Compressor Unit: Facilitates ammonia pressurization and unloading processes in chemical engineering. |

Our Diverse Product Range

In addition to compressors, our company offers a plethora of industrial products tailored to meet various needs. We specialize in agricultural gearboxes, power output shafts, sprockets, hydraulic couplings, worm gear reducers, racks, roller chains, pulleys, planetary gearboxes, timing pulleys, and bushings. We pride ourselves on delivering high-quality products at preferential prices, along with outstanding customer service. Customization is available upon request with drawings and samples.

Frequently Asked Questions

- What advantages do your compressors offer?

- How can I trust your products?

- Do you provide warranties for your equipment?

- Can I visit your facility?

- What are your payment options?

“`

Performance Characteristics of Nitrogen Compressors

Nitrogen compressors are instrumental in a variety of industrial applications, distinguished by several performance characteristics that enhance their utility and efficiency. Here are some key points that define their performance:

- High Efficiency: Nitrogen compressors are designed to provide maximum output with minimum energy consumption. This efficiency is achieved through advanced engineering and innovative technology, allowing for reduced operational costs.

- Variable Flow Rates: These compressors can adapt to various flow rate requirements, making them suitable for different applications. The ability to modulate flow ensures that industries can optimize nitrogen supply based on demand.

- Robust Design: Built to withstand harsh operational environments, nitrogen compressors feature durable materials that enhance their longevity and reliability. This robustness reduces the need for frequent maintenance and downtime.

- Purity Control: Many nitrogen compressors are equipped with sophisticated filtration systems that ensure high nitrogen purity levels, which is crucial in sectors that require stringent quality standards.

- Low Noise Levels: Advanced noise reduction technologies are incorporated to minimize operational noise, making these compressors suitable for use in environments where sound levels are a concern.

Types and Characteristics of Nitrogen Compressors

Nitrogen compressors come in various types, each with unique characteristics tailored to specific applications. The main types include:

- Reciprocating Compressors: Known for their high compression ratios and efficiency, these compressors utilize a piston mechanism to compress nitrogen. They are typically used in applications where high pressure is required.

- Rotary Screw Compressors: These compressors use two rotating screws to compress nitrogen, offering continuous flow and minimal pulsation. They are favored in industrial settings that demand steady output.

- Centrifugal Compressors: Utilizing a rotating disk, centrifugal compressors are ideal for high flow rates and lower pressure applications. They are commonly found in large-scale industrial processes.

The materials used in manufacturing nitrogen compressors significantly influence their performance:

- Aluminum: Lightweight and resistant to corrosion, aluminum compressors are ideal for mobile applications. However, they may not withstand high pressures as effectively as steel.

- Stainless Steel: Known for its strength and resistance to corrosion, stainless steel compressors are durable and can handle high-pressure operations, making them suitable for challenging environments.

- Cast Iron: These compressors are robust and can endure high operational pressures, providing longevity but at the expense of weight and portability.

Applications of Nitrogen Compressors in Various Industries

The versatility of nitrogen compressors allows them to serve critical roles across multiple industries:

- Refrigeration and Oil Industry: Nitrogen compressors are used for purging and inerting systems, preventing oxidation and maintaining system integrity.

- Food Industry: In food packaging, nitrogen is utilized to displace oxygen, extending shelf life. Compressors ensure a steady supply of nitrogen for this purpose.

- Medical Industry: Nitrogen serves as a crucial component in various medical applications, including cryopreservation and gas delivery systems, where consistent purity is paramount.

- Semiconductor Manufacturing: The tech industry relies on high-purity nitrogen to create an inert atmosphere during the manufacturing process, where even minor contaminants can cause significant issues.

- Chemical Industry: Nitrogen compressors support numerous chemical processes, providing inert environments that mitigate the risk of fire and explosion.

Future Development Trends and Opportunities for Nitrogen Compressors

The nitrogen compressor market is poised for growth, driven by technological advancements and increasing demand across various sectors. Future trends include:

- Automation and Smart Technology: The incorporation of IoT and smart sensors is expected to enhance monitoring and control, leading to improved efficiency and reduced operational costs.

- Sustainability Practices: With a global focus on sustainability, manufacturers are likely to develop more energy-efficient and eco-friendly compressors, addressing environmental concerns.

- Expansion in Emerging Markets: As industries in developing countries expand, the demand for nitrogen compressors will increase, presenting significant growth opportunities for manufacturers.

In conclusion, the future of nitrogen compressors is bright, with ample opportunities for innovation and market expansion.

Choosing the Right Nitrogen Compressor

Selecting a suitable nitrogen compressor requires careful consideration of several factors:

- Application Requirements: Understanding the specific needs of your industry and how nitrogen is utilized will guide your choice of compressor.

- Flow Rate and Capacity: Assessing the required flow rate and ensuring the compressor can meet capacity demands is crucial for operational efficiency.

- Pressure Requirements: Different applications require varying pressure levels. Ensure the compressor can achieve and maintain the necessary pressure.

- Purity of Nitrogen: Depending on the industry, the purity level of nitrogen may be critical. Choose a compressor equipped to deliver the required purity standards.

- Regulatory Compliance: Ensure that the compressor meets relevant industry standards and regulations to avoid compliance issues.

- Safety Features: Assess the safety mechanisms in place to protect against potential hazards during operation.

Conclusion

Nitrogen compressors are vital in various industries, providing crucial services that enhance operational efficiency, safety, and product quality. Understanding their performance characteristics, types, applications, and future trends is essential for making informed decisions in selecting the right equipment. As technology advances, the value and significance of nitrogen compressors will only continue to grow.

Author: Dream

All the content of the page is from the Internet, the content is only as a reference for product selection, our products are replacement parts and not original spare parts; we are not the holder of the original trademarks of the content, our products are only suitable for after-sales replacement parts and not original spare parts, our replacement parts can be perfectly adapted to the original spare parts; if you need to buy original spare parts, please contact the original factory to buy. If you want to buy original spare parts, please contact the original supplier for purchase.

“`html

“`html

“`html

“`html